Call Us

07971258519

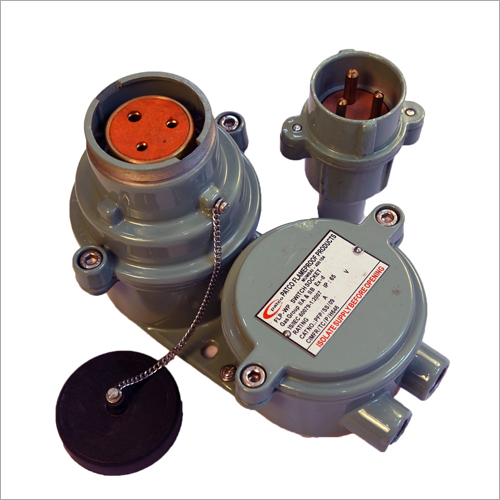

Flameproof Switch Socket With Plug upto 32A 415V 5 PIN

100.00 INR/Unit

Product Details:

- Mechanical Life >10,000 operations

- Finish Type Epoxy Powder Coated

- Automation Grade Manual

- Response Time Instantaneous mechanical operation

- Protection Level IP65 / IP66

- Temperature Range -20C to +55C

- Circuit Type AC Power Distribution

- Click to view more

X

Flameproof Switch Socket With Plug upto 32A 415V 5 PIN Price And Quantity

- 100.00 INR/Unit

- 1 Number

- Neoprene

- 95% RH

- Petroleum, Chemical, Pharmaceutical & Similar Hazardous Areas

- Outdoor / Hazardous Zone

- Flameproof, Explosion Proof, Weatherproof

- IS/IEC 60079-1 & 60079-7, IS/IEC 60529

- IIB or IIA & IIB + H2 (on request)

- Provided with internal/external earthing

- Powder coated MS / SS as per requirement

- Brass with Tin/Nickel Plating

- IP65 / IP66

- Complete set with socket, plug and external hardware

- 2 x 3/4 inch (standard), others on request

Flameproof Switch Socket With Plug upto 32A 415V 5 PIN Product Specifications

- 415V AC

- Upto 32A, Standard (Customizable options available)

- -20C to +55C

- IP65 / IP66

- Instantaneous mechanical operation

- 32A

- 415V

- Approx 2.8 kg (for 32A with plug)

- >100 M at 500V DC

- 5 (3P+N+E)

- Surface (Wall) Mounting

- 2 m

- Single

- AC Power Distribution

- Epoxy Powder Coated

- -20C to +55C

- Manual

- >10,000 operations

- Grey / Silver

- 32A

- Neoprene

- 95% RH

- Petroleum, Chemical, Pharmaceutical & Similar Hazardous Areas

- Outdoor / Hazardous Zone

- Flameproof, Explosion Proof, Weatherproof

- IS/IEC 60079-1 & 60079-7, IS/IEC 60529

- IIB or IIA & IIB + H2 (on request)

- Provided with internal/external earthing

- Powder coated MS / SS as per requirement

- Brass with Tin/Nickel Plating

- IP65 / IP66

- Complete set with socket, plug and external hardware

- 2 x 3/4 inch (standard), others on request

Flameproof Switch Socket With Plug upto 32A 415V 5 PIN Trade Information

- 2000 Number Per Month

- 5 Days

- All India

Product Description

We have been a profound supplier of FLP Switch Socket in the market. This is made in several specifications for use at different places to meet the demands of our customers. Finest of raw material and hi tech machinery is used for making FLP Switch Socket as per the prevailing industrial standards.

Other details:

Condition- New

Features- Durable

Prices may vary with sizes and specifications

Rugged Construction with Trusted Safety

This switch socket assembly is crafted from powder-coated mild steel or stainless steel with neoprene gaskets and tin/nickel-plated brass pins. Its robust enclosure is meticulously designed to prevent ignition in flammable environments, conforming to international standards. IP65/IP66 ratings guarantee dust-tight and water-resistant protection, making it an ideal choice for both indoor and outdoor hazardous areas.

Versatile Applications Across Industries

Engineered for versatility, this switch socket is widely used in petroleum refineries, chemical factories, pharmaceutical plants, and similar settings where flammable gases may be present. Its durable construction, high insulation resistance, and mechanical lifespan exceeding 10,000 operations make it apt for continuous and reliable operation in humid, challenging, or potentially explosive locations.

FAQs of Flameproof Switch Socket With Plug upto 32A 415V 5 PIN:

Q: How does the flameproof switch socket ensure safety in hazardous environments?

A: The enclosure is designed to prevent sparks or arcs from igniting surrounding gases or vapors. It adheres to IS/IEC 60079-1 & 60079-7 standards, making it suitable for Gas Groups IIA, IIB, and, on request, IIB + H. It also provides ingress protection of IP65/IP66, ensuring dust and water do not compromise safety.Q: What is the typical usage of this flameproof switch socket and plug?

A: This device is primarily used for connecting and distributing AC power in hazardous or outdoor environments, such as petroleum, chemical, and pharmaceutical industries where flammable gases might be present. It is suitable for both temporary and permanent installations.Q: When should I select a switch socket with explosion-proof features?

A: Explosion-proof switch sockets are crucial when your workplace is classified as a hazardous zone with risk of explosive atmospheres. If your operations involve flammable substances, compliance with explosion protection standards becomes mandatory for safety and legal compliance.Q: Where can this product be installed?

A: This switch socket is surface-mounted and designed for installation on walls in both indoor and outdoor locations, especially where other enclosures might fail due to weather or the presence of hazardous substances.Q: What is the process of installing and wiring the switch socket?

A: Installation involves surface mounting the unit, connecting the power cables via two standard 3/4 cable entries (others available on request), and ensuring proper earthing using provided points. A professional electrician should carry out installation to guarantee safety and correct conformity.Q: How does the product benefit users in industrial settings?

A: It offers long-term reliability, minimizes the risk of accidental ignition, operates efficiently across a wide temperature range, and withstands humid environments up to 95% RH. The robust make and high-quality materials require minimal maintenance while enhancing workplace safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email