Call Us

07971258519

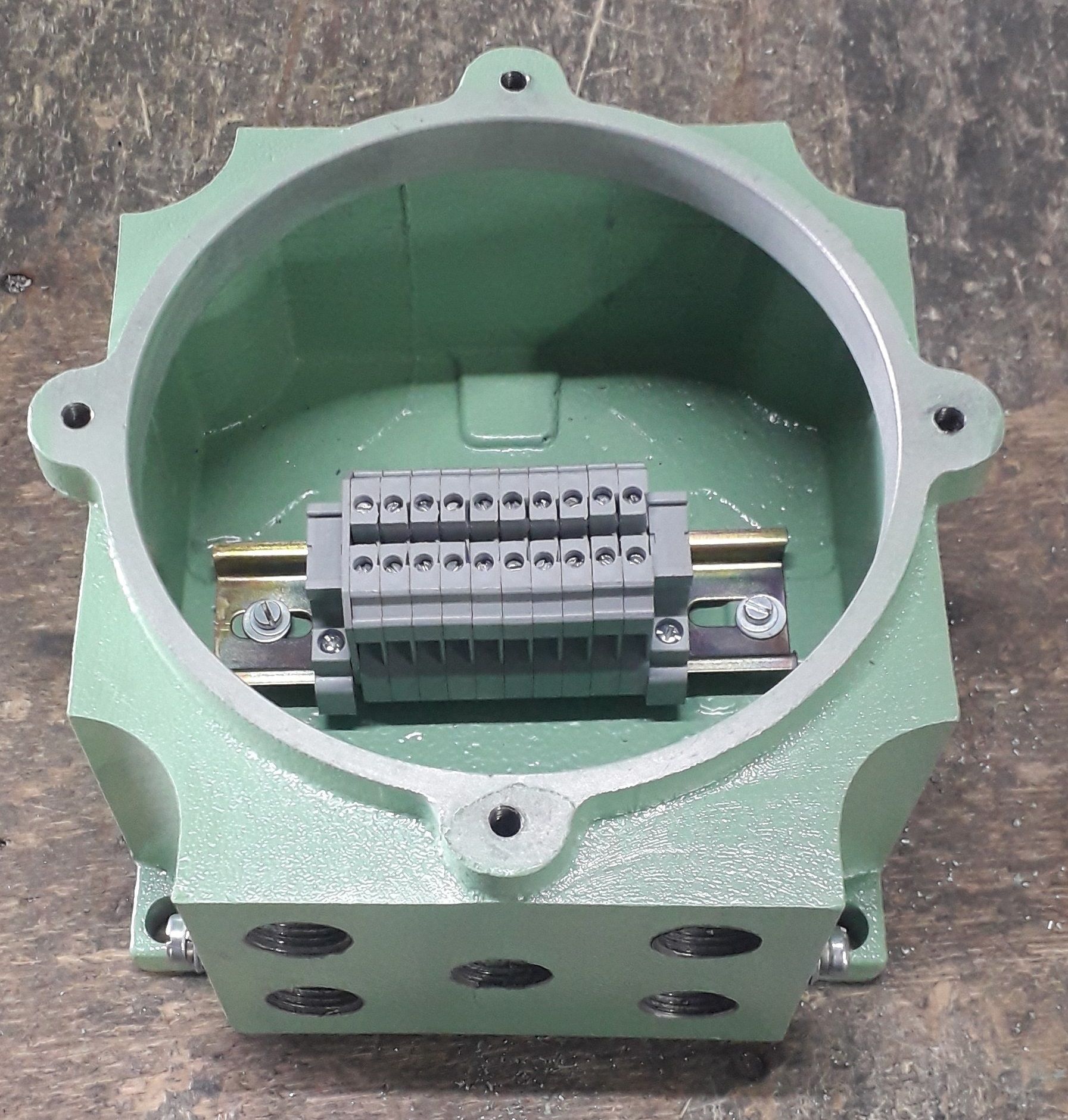

FLAMEPROOF WEATHERPROOF JUNCTION 150 X 150 X 110MM

1000 INR/Piece

Product Details:

- Product Type Junction Box

- Material Other

- Protection Level Flameproof, Weatherproof (IP65/66)

- Surface Treatment Smooth finish, anti-corrosive coating

- External Size 150 mm x 150 mm x 110 mm

- Thickness 3-4 mm (typical for cast enclosures)

- Paint Finishing Epoxy Powder Coated

- Click to view more

X

FLAMEPROOF WEATHERPROOF JUNCTION 150 X 150 X 110MM Price And Quantity

- 1 Number, Number

- 1000 INR/Piece

FLAMEPROOF WEATHERPROOF JUNCTION 150 X 150 X 110MM Product Specifications

- 150 mm x 150 mm x 110 mm

- Flameproof, Weatherproof (IP65/66)

- Junction Box

- Epoxy Powder Coated

- Grey

- 3-4 mm (typical for cast enclosures)

- Other

- Smooth finish, anti-corrosive coating

- Approx. 3.2 kg

- 150 x 150 x 110 mm

FLAMEPROOF WEATHERPROOF JUNCTION 150 X 150 X 110MM Trade Information

- 20000 Number, Number Per Month

- 5 Days

- All India

Product Description

| TECHNICAL SPECIFICATION | ||||||||||||

| CAT NO : | PFP/JB/150 | |||||||||||

| Type of Ex-Protection : | AS PER IS / IEC-60079-1:2007 | |||||||||||

| Zone Classification : | Zone 1 & Zone 2 | |||||||||||

| Gas Group : | GAS GROUP I, IIA, IIB | |||||||||||

| Ingress IP Protection : | IP-65 IS/IEC60529-2001 | |||||||||||

| Material of contraction : | Die Cast Aluminum Alloy LM6 | |||||||||||

| TERMINAL : | AS PER CLIENT REQUIREMENTS | |||||||||||

| Paint : | Epoxy Polyester Powder Coating | |||||||||||

| Earthling : | INTERNAL : 01 NOS & EXTERNAL : 2 NOS | |||||||||||

| Cable Entry : | AS PER CLIENT REQUIREMENTS | |||||||||||

| Hardware : | Stainless Steel | |||||||||||

Versatile Protection for Hazardous Locations

Designed for use in explosive and hazardous areas, this flameproof and weatherproof junction box meets strict requirements for Zone 1 & 2 (Gas group IIA & IIB). Its robust enclosure, silicone gaskets, and stainless steel fastening guarantee safety and reliability, making it ideal for demanding industries such as petrochemicals and refineries.

Flexible Cable Management & Installation

The junction box offers multiple customizable, threaded cable entry knockouts, accommodating a range of wiring specifications. Designed for easy wall or surface mounting, its square shape with rounded corners provides optimal accessibility for installation, maintenance, and future expansion.

Durable Construction for Longevity

Built with a 3-4 mm thick cast enclosure and finished with anti-corrosive epoxy powder coating, this junction box withstands harsh operational environments. It offers ingress protection up to IP66, ensuring resilience against dust and water, while maintaining reliable performance in temperatures from -20C to +60C.

FAQs of FLAMEPROOF WEATHERPROOF JUNCTION 150 X 150 X 110MM:

Q: How does the junction box ensure safety in hazardous environments?

A: The box is certified for use in Zone 1 & Zone 2 hazardous gas areas (Gas group IIA & IIB), with a flameproof and weatherproof IP65/IP66 enclosure. Its silicone rubber gasket and stainless steel fasteners prevent ingress of dust, water, and explosive gases, reducing the risk of ignition.Q: What are the cable entry options and how can they be customized?

A: This junction box features multiple, threaded knockouts for cable entries, which can be customized based on the projects requirements. You can specify the type and number of knockouts needed, allowing for flexible wiring and integration with various electrical systems.Q: Where is this junction box typically installed?

A: It is primarily used in hazardous and explosive areas like petrochemical plants, refineries, and similar industrial environments. Its wall or surface mounting design and robust build make it suitable for both indoor and outdoor applications.Q: What are the main benefits of using this flameproof junction box?

A: The main benefits include enhanced safety in hazardous locations, robust weatherproofing, customizable cable management, and long service life. Its certified protection helps prevent accidents while simplifying maintenance and installation processes.Q: Can the box accommodate a range of voltages and currents?

A: Yes, the enclosure is rated for up to 415V AC and currents up to 63A, making it suitable for a wide variety of industrial electrical connections and distribution requirements.Q: What is the process for installation and maintenance?

A: Installation involves mounting the box securely on a wall or surface, inserting cables through the threaded knockouts, and fastening the cover with stainless steel screws for a secure, weatherproof seal. Routine inspection is recommended to ensure gaskets and seals remain intact for ongoing protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email